Home > Products > coal and charcoal machine > Small Charcoal Machine/Jute Sticks Charcoal Powder Making Machine

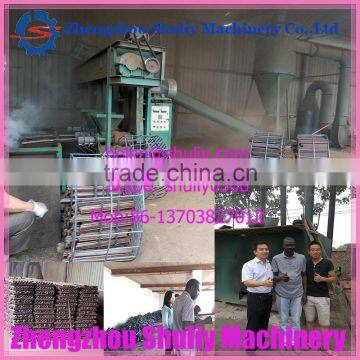

Small Charcoal Machine/Jute Sticks Charcoal Powder Making Machine

- Qingdao Port

- T/T Credit Card PayPal

You May Like

-

Continuously Type Jute Stick Charcoal Furnace Charcoal Powder Making Machine 008613703827012

-

Charcoal Producing Furnace With Smokeless 008613703827012

-

Charcoal Making Machine Jute Sticks Charcoal Making Machine Bamboo Waste Charcoal Making Machine Carbonization s 008613703827012

-

Waste Paper Briquette Machine Automatic Wood Sawdust Briquette Machine for Bbq

-

Coal Maker/Square Charcoal Making Machine/charcoal Briquette Machine//0086-13703827012

-

High Capacity Coal Crushing Machine/ Movable Crushing Plant 0086-13703827012

Product Details

| Condition | New | Production Capacity | 350-380kg per hour | |

| Motor Type | AC Motor | Power(W) | 18.5kw | |

| Place of Origin | Henan, China | Brand Name | SHULIY | |

| Model Number | SL-ZB | Dimension(L*W*H) | 1.9*0.6*1.8m | |

| Certification | ISO CE | Warranty | 1 year | |

| After-sales Service Provided | Engineers available to service machinery overseas |

Product Description

Small charcoal machine/Jute sticks charcoal powder making machine

introduction

Briquettes are made by grinding Biomass and sawdust into a homogeneous pulp and forming them into a briquette under very high pressure. High pressure & pressing releases one of the natural components of wood - lignin which has the property of becoming liquid at high pressure (temperature) and, as it subsequently cools, it binds the wood together in its new form Briquettes.

Requirment of the raw material

1-For using material of two or more types, It should be mixed in suitable form.

2- Size : less than 5mm , if the material can not accheive the reuirment, it should be crush first.

3- Moisture :8-12%,If raw material has high moisture it should be reduced by Sun drying or using flash drier

Raw material:

Any types of Agro-forestry waste Such as maize stalks, soybean stalks, broomcorn stalks, cotton stalks, rape stalks, peanut plants, sunflower stalks, bamboo saw dust, bagasse, wood chips, rice husk, coffee husk,coir pith, jute sticks, groundnut shells, Bamboo , wood , strawdust, Mustard stalk and cotton stalks .etc

finished product:

The final bio-fuel briquette is made by the advanced biomass briquetting machine. After the processing of drying, compressing under the high pressure and temperature, the biomass briquette is characterized by high density, small in size, better combustion, capable as the substitute for the superior coal or firewood. This bio-fuel briquette is 45-80mm in diameter, occurs in the hollow quadrangular or hexagonal cylinde or hollow hexagonal with a 15-20mm hole through the body. The bio-fuel carbon maintains the cleanliness and hygiene, and is suitable for family heating and barbecuing. There is a huge need in the international market, for it is capable as the substitute for the superior coal or heavy oil to the Industrial steam boiler, or the industrial raw material for the further processing into the activated carbon, mosquito coils and explosives

application:

As the need of pollution free environment, the product has a large scope of marketing. The briquettes can be used as a substitute of any fuel in following fields

Boilers : It can be used in the boilers of Paper Mills, Sugar Mills, Dyeing houses, leather, lamination industries, Vanaspati units, Food Processing Units, Oil Extraction Units, Solvent Extraction Plant and many other plants and industries..

Furnace & Foundries : It can be used for metal heating & melting (where melting point is less than 1000d/cel.)

Brick Kilns It is the total, substitute of steam coal.

Residential & Commercial Heating For winter heating in Cold areas and Hotels, Canteens, Cafeterias and house hold kitchen appliances etc.

Partameter:

Model | SL-1 | SL-2 | SL-3 |

Capacity | 120-180kg/h | 180-240kg/h | 350--380kg/h |

Power | 15kw | 22kw | 18.5--22kw |

Net weight | 0.7T | 0.8T | 0.7T |

Package size | 1.65*0.6*1.6 | 1.9*0.6*1.8 | 1.9*0.6*1.8 |

Diameters of product | 50 mm | 50 mm | 80mm |

Moisture content of t he raw materials | Moisture content is 8-12%. | ||

Requirements on the size of the materials: the diameters of the raw materials are between 3mm and 5mm | |||

If you are interested in our product, please feel free to contact me.

Contact Us

- Zhengzhou Shuliy Machinery Co., Ltd.

- Contact namelinda Meng Chat Now

- Phone86-371-86636882

- AddressNo.1394 East Hanghai Road, Economic-technological development Area, Zhengzhou,Henan, Zhengzhou, Henan

Product Categories

New Products

-

Wall Cement Rendering Machine/Wall Plastering Machine/Troweling Machine for the Wall//oo86-15838059105

-

Stainless Steel Automatic Rendering Machine/wall Painting Machine/plastering Machines for Sale//oo86-15838059105

-

Hot Sale Auto Wall Plastering Machine /wall Plastering Rendering Machine/wall Cement Spray Plaster Machine//oo86-15838059105

-

Automatic Cement Wall Rendering Machine/ Plastering Machine for Wall//oo86-15838059105

-

China Cheap Price Automatic Wall Cement Plastering Machine//oo86-15838059105

-

New Technology Low Price Render Automatic Wall Plastering Machine for Sale//oo86-15838059105

-

Cement Render Machine for Wall Automatic Render Machine Wall Plaster Machine//oo86-15838059105

-

Construction Site Plastering Machine | India Wall Plastering Machine | Cement Plastering Machine for Wall//oo86-15838059105

-

New Type Factory Cheap Price Automatic Wall Plastering Machine/render Machine/auto Rendering Machinery//oo86-15838059105

-

Spray Render Machine for Houses With Clay//oo86-15838059105

-

Best Price Wall Plastering Equipment,wall Cement Spray Plaster Machine//oo86-15838059105

-

Wall Plastering Machine/Auto Wall Rendering Machine//oo86-15838059105

-

New Advanced Automatic Wall Plastering Machine//oo86-15838059105

-

China Automatic Wall Plastering Machine

-

Best Quality SLCW-180 Solid-liquid Seperating Machine for Cow Dung//0086-15838061756

-

Best Quality Drum Type Soil Screening Machine//0086-15838061756

-

Wall Plastering Materials Auto Rendering Machine

-

2015 With ISO Conveient India Wall Plastering Machine

-

Best Quality Horizontal Fertilizer Mixer 0086-15838061756

-

Hot Sale Organic Fertilizer Granule Making Machine//0086-15838061756

-

2015 the BEST Wall Spray Plastering Machine

-

Auto Wall Rendering Machine Machine for Plastering Wall

-

Best Quality Organic Fertilizer Crusher//0086-15838061756

-

Electric Crane for Construction/small Construction Crane

Popular Searches

- coal briquett

- artificial coal

- briket

- coal powder balling machine

- press wood briquete

- woods agricultur

- briket press machine

- charcoal briket machine

- coal press machine

- pini kay briquette machine

- a pressure spong

- a products briquett

- a products briquete

- ash roller

- briqueting machine charcoal machine

- briquetes manufacture

- briquete making machine

- beehive briquette machine

- briquet coal machine

- charcoal briquett machine

- charcoal briquetter machine

- coal equipements supplier

- coal machin

- excell iron

- fine pellet

- homemade briquette machine

- peat machine

- scrap press briqueting

- coal briquetter

- performance coal

Recommended Products

- Factory Lowest Price Shisha Hookah Charcoal Briquette Press Machine Tunisia Shisha Charcoal Making Production Machine

- Industrial Charcoal Sticks Briquette Extruder Machine

- Fully Automatic Wood Waste Sawdust Screw Briquetting Charcoal Making Machine Biomass Briquette Machine

- Powdermaking Powder Coal Ball Press Equipment Biomass Machine Briquette Line Production Biomass Briquetting Plant

- 2024 Guide to Coal Briquette Machine ROI Calculation

- How to Choose a Briquette Machine: 5 Mistakes to Avoid

- Custom Shape Briquette Press Supplier in Germany

- Best Briquette Machine Manufacturer for Mining Industry

- Exclusive Discount for Bulk Orders in Briquetting Equipment

- Why Our Hydraulic Press Outperforms Mechanical Models

- Briquette Machine With 3D Animation Demo

- 30% Denser Briquettes With Advanced Roller Design

Find Similar Products By Category

- Manufacturing & Processing Machinery > Mining Machinery > Briquette Machines

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

linda Meng

Hi there! Welcome to my shop. Let me know if you have any questions.

linda Meng

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile